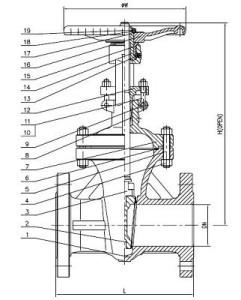

Flange Full Lift Safety Valves can be used on systems where the discharge is relatively simple. The pressure in the discharge system can be Atmospheric, at a constant level or where the pressure may build up to a maximum of 10% of the set pressure. When a constant back pressure exists, the valve should be set at the differential pressure

Design verification: all design options and the various effects of system conditions, back pressure etc.

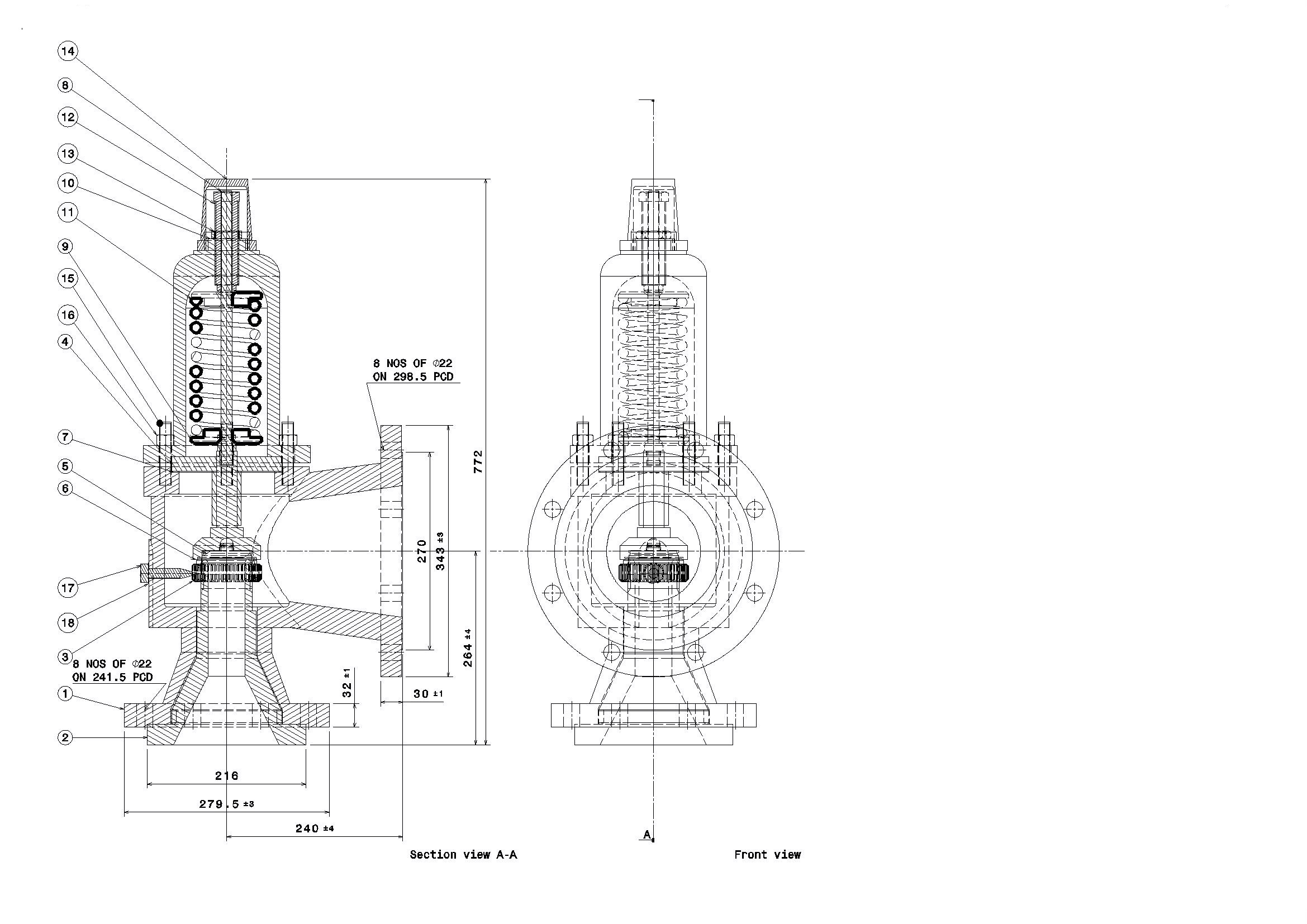

.jpg)

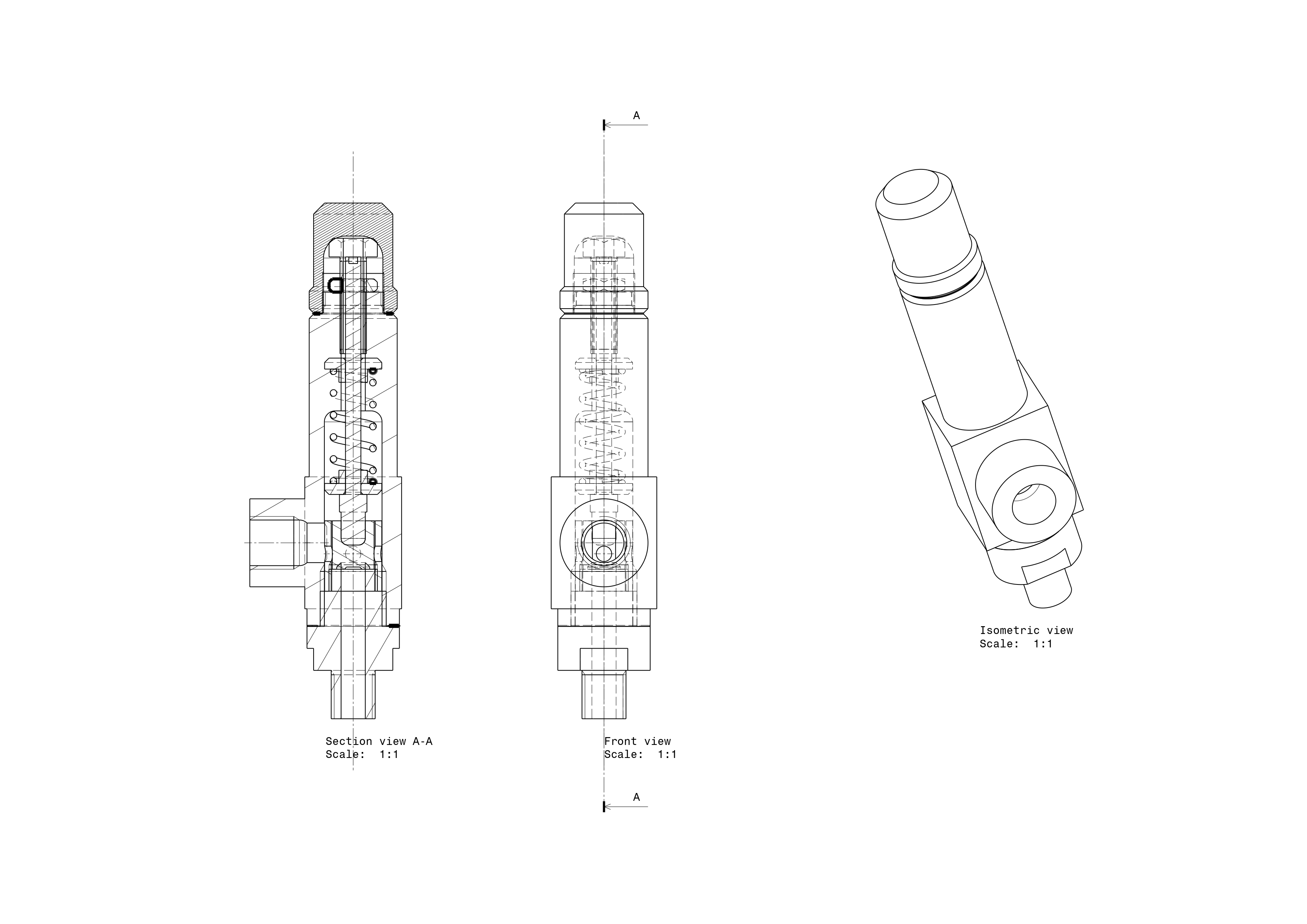

.jpg)

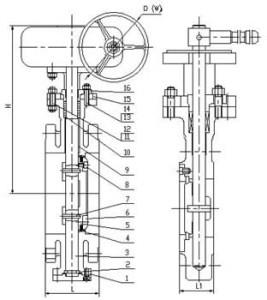

.jpg)

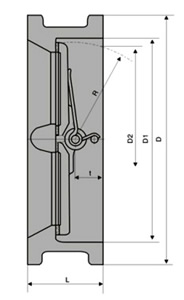

.jpg)